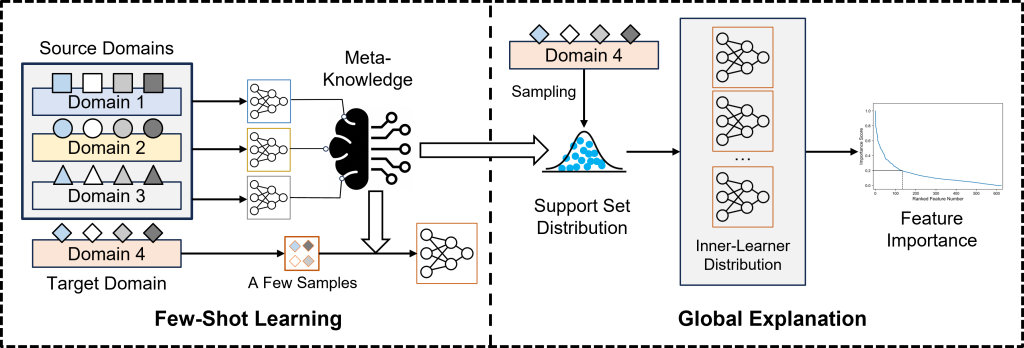

Recently, our paper titled “Explainable few-shot learning for online anomaly detection in ultrasonic metal welding with varying configurations” has been published on Journal of Manufacturing Processes. The paper was co-authored by Yuquan Meng, Kuan-Chieh Lu, Zhiqiao Dong, Shichen Li, and Prof. Chenhui Shao.

Modern manufacturing is featured by rapid reconfiguration and agile adaptation that necessitate varying process configurations. In ultrasonic metal welding, a process configuration can be defined by materials, welding parameters, surface conditions, etc. Changing process configurations may lead to very different data distributions. In such cases, it is necessary to collect labeled data from the new scenarios and re-train classification algorithms or even build completely different algorithms. Acquiring a significant volume of training data can be time-, labor-, and resource-intensive, which is highly undesirable in manufacturing. This paper proposes a explainable few-shot learning (FSL) approach which can train models that can perform well on new tasks with minimal data with high explainability. This approach not only exhibits excellent adaptability to new tasks but can also serve as an effective feature selection method.

Read the full paper here.