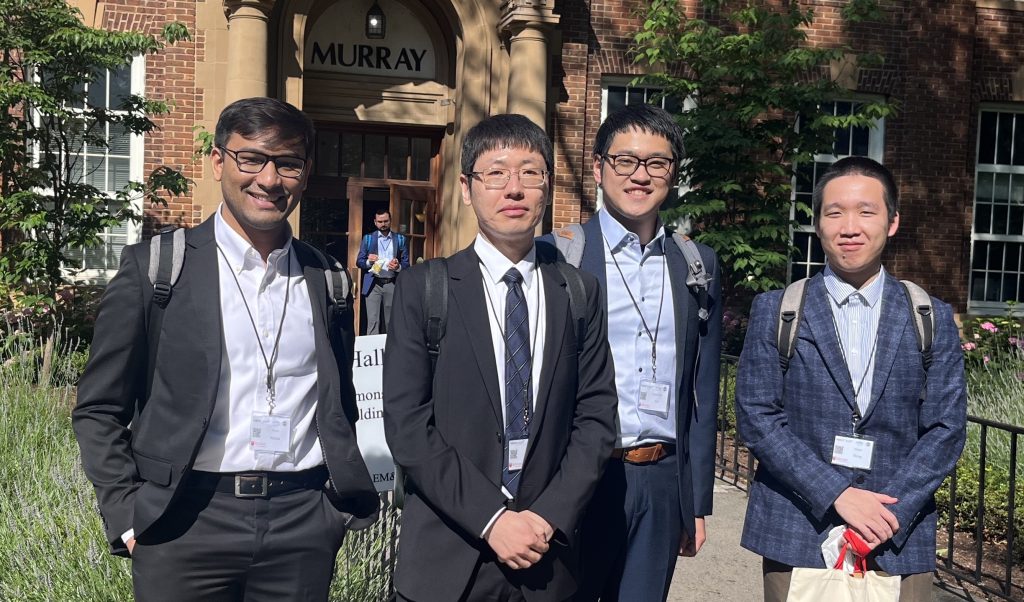

Our PhD students Kuan-Chieh, Zhiqiao, and Manan published papers and present their research at MSEC 2023 & NAMRC 51 at Rutgers University this summer.

Kuan-Chieh’s paper titled “Online Cost-Effective Classification of Mixed Tool and Material Conditions in Ultrasonic Metal Welding: Towards Integrated Monitoring and Control” has been published at MSEC 2023.

Ultrasonic metal welding (UMW) is vital in manufacturing industries like electric vehicles and automotive assembly. However, it is sensitive to process disturbances that affect joint quality. Effective online monitoring is crucial for detecting anomalies and adjusting parameters promptly. In recent work, the cost-efficiency of monitoring systems is often overlooked. This study focuses on three key factors: sensor selection, data sampling rate, and signal fraction. We use discrete wavelet transformation (DWT) for feature extraction and a multi-layer perceptron (MLP) classifier to identify welding disturbances, such as tool and material conditions. Case studies reveal that choosing the right signal fraction and a subset of sensors can match full-length sensor performance, providing a cost-effective solution that enhances real-time control opportunities.

Zhiqiao’s paper titled “A Fast and Cost-Effective Imaging System for Fine-Scale Tool Condition Monitoring in Ultrasonic Metal Welding” has been published at MSEC 2023.

Tool condition monitoring (TCM) is crucial in ultrasonic metal welding (UMW) due to rapid tool degradation. Tool health affects joint quality and incurs significant maintenance costs. Current TCM methods are either indirect or expensive, leading to delays and high expenses. To address this, a cost-effective TCM system has been developed. It comprises a macro lens and a Raspberry Pi (RPI) high-quality camera on a linear rail controlled via RPI GPIO. Coaxial illumination enhances tool surface features, and image processing techniques characterize tool surface profiles. This system effectively reconstructs fine-scale geometric features, enabling responsive and reliable TCM for UMW.

Manan presented his work titled “A federated learning approach to mixed fault diagnosis in rotating machinery”, which has been published in the Journal of Manufacturing Systems.